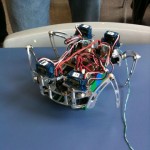

More progress on the Outdoor Robot

I’ve made a number of additions to my Outdoor Robot project, including motor mounts and getting the steering set up.

I’ve made a number of additions to my Outdoor Robot project, including motor mounts and getting the steering set up.

The motor mounts are milled from half-inch aluminum plate, holding two GHM-04 motors plus shaft encoders from Lynxmotion. These motors should be plenty powerful enough and also have a good top speed for this application. It took me a few hours to mill out the two mounts using my CNC Sherline. I need to make some couplings and drive shafts to get the motors connected to the rest of the drive train.

The steering mechanism is from the original RC truck chassis, I just needed to do something about controlling the servos. I set up an ATMega88 that sends the necessary pulse train for servo control. Eventually this chip will communicate with the Overo over CAN, also talk to the the motor controller board I purchased from Pololu, and will have a custom circuit board. For today its only task is to control the steering servos, accepting keyboard input from a serial console.

I needed to calibrate the servo pulse train to the desired positions of the steering mechanism as its installed. Normally servos are a wide range of motion (most go 180 degrees) and accept a pulse train with widths between 1ms and 2ms. These servos do that just fine, except there was no way to know where “center” was in relationship to the wheels. I also wanted to make sure I was getting approximately the same angle on the front and back steering. I created a little jig using some right-angle machinist squares plus clamps plus a ruler. Finding the center position was easy, then I mapped out the servo position required to move the wheel indicator in half-centimeter increments. I ended up with a table of 25 different entries for the front and the back steering servos that give me consistent control. Given the slop in the steering mechanism from this truck chassis, I figured this was good enough.

Here is a little movie of the steering in action. I set up the camera on a tripod then was pressing keys on my laptop that instructed the microprocessor to move the servos to particular locations. I have fully independent control over the front and back steering, and it really looks awesome.

You might also notice in the top right corner of that picture my new Rigol 50Mhz dual channel oscilloscope. Its a nifty piece of equipment, lets me look at signals like the servo pulse train easily. I picked it up from eBay for a reasonable price and so far (having only used it for a day) am very pleased. I recently also bought a Saleae Logic analyzer that I’ve been pretty happy with. I’ve been using it with the “early preview” version of the Mac software. It has bugs but so far none have prevented me from getting the job done. I’d recommend both pieces of test equipment for your own bench.